- ETA approval for the FORCE ONE system

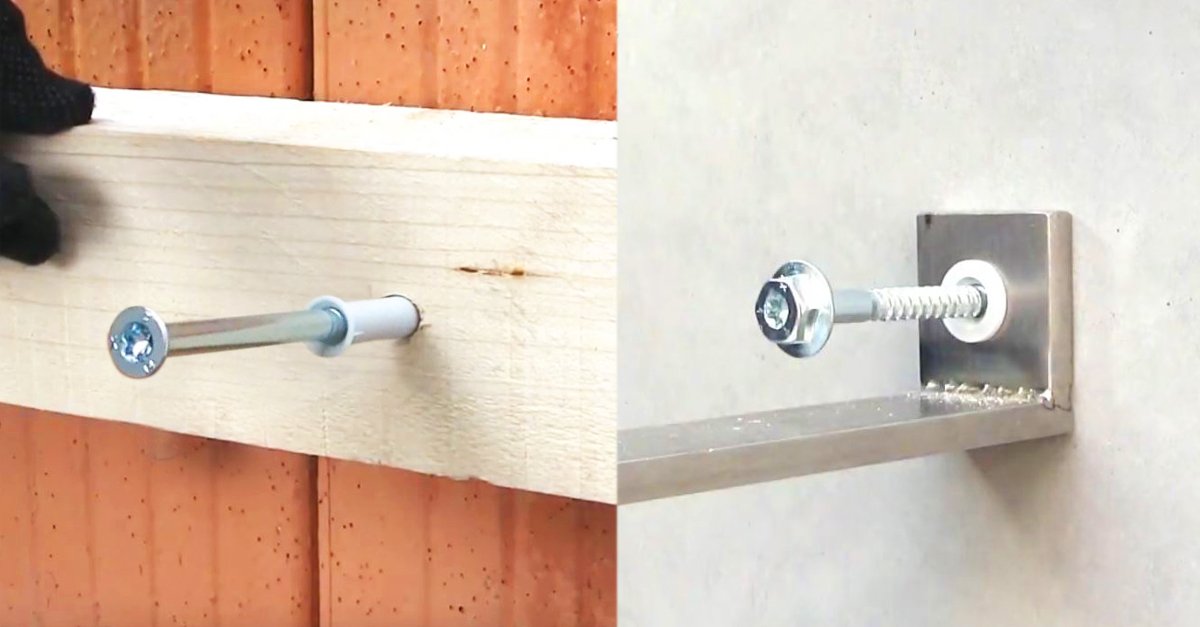

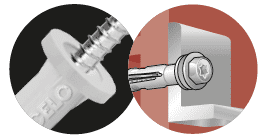

- New concrete screw BTS6 E long with M8 connection thread

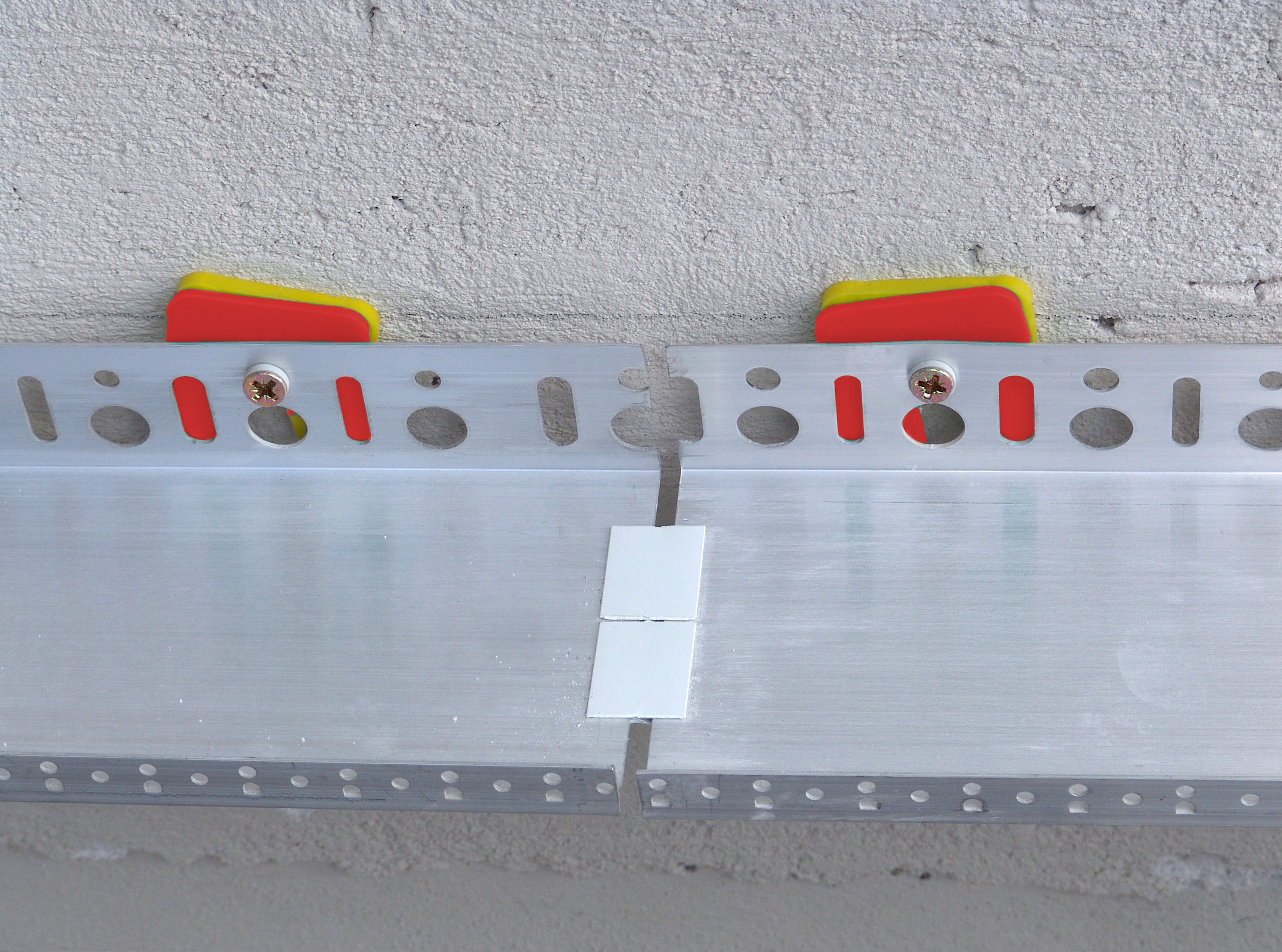

- Innovation ResiTHERM® 16 - winner of the BIG SEE award 2023

- CELO 60th Birthday

- Our highlights of the BAU fair 2023

- New pre-nailing drill bit SDS Plus for FORCE ONE

Customer Service

Do you need help?

Choose a location

to view contact options

-- Choose --

-

CELO Chile

CELO Chile

-

CELO Croatia

CELO Croatia

-

CELO France

CELO France

-

CELO Germany

CELO Germany

-

CELO Hungary

CELO Hungary

-

CELO Latvia

CELO Latvia

-

CELO Morocco

CELO Morocco

-

CELO Poland

CELO Poland

-

CELO Romania

CELO Romania

-

CELO Slovakia

CELO Slovakia

-

CELO Spain

CELO Spain

-

CELO Sweden

CELO Sweden

-

CELO UAE

CELO UAE

-

CELO USA

CELO USA

Published: 2021-06-01 | Updated: 2024-07-27