- How to decide the right self-drilling screw?

- Why use CE approved anchors?

- Seismic approval Apolo MEA fixings

- Screws Stripping off

- Delayed fractures

Customer Service

Do you need help?

Choose a location

to view contact options

-- Choose --

-

CELO Chile

CELO Chile

-

CELO Croatia

CELO Croatia

-

CELO France

CELO France

-

CELO Germany

CELO Germany

-

CELO Hungary

CELO Hungary

-

CELO Latvia

CELO Latvia

-

CELO Morocco

CELO Morocco

-

CELO Poland

CELO Poland

-

CELO Romania

CELO Romania

-

CELO Slovakia

CELO Slovakia

-

CELO Spain

CELO Spain

-

CELO Sweden

CELO Sweden

-

CELO UAE

CELO UAE

-

CELO USA

CELO USA

Screws Stripping off

Stripping off occurs when tension generated by assembly torque is higher than nut shear strength. Consequently we notice that screw turns into the hole even reducing torque value.

Parameters like torque, engagement, hole diameter, friction… could affect stripping torque values. In these cases we recmmend to verify materials, design and final requirments to determine the best solution and assembly parameters.

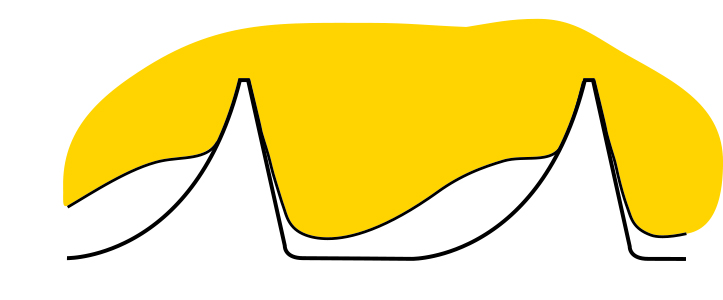

The following figure shows the distribution of plastic created by REMFORM® screw. The larger contact surface with the thread flanks provides better resistance to stripping.