What is the Factor of safety?

The factor of safety is used in fastening technology to indicate the recommended or permissible load capacity of a product.

If a product is loaded with the maximum recommended or permissible load capacity, it must be ensured that no failure occurs under normal circumstances. The safety factor indicates the difference between the specified load capacity and the actual failure load.

Safety factor for non-approved products

Safety factors are necessary due to significant inaccuracies and occasional disregard of installation rules when installing anchors (e.g., forgetting to clean the drill hole, not adhering to the drill hole depth or edge distances, etc.). Nonetheless, the anchor must not fail. It is important to note that safety factors cannot always compensate for serious installation errors. In such cases, the responsibility lies with the craftsman rather than the anchor manufacturer if the fixing fails.

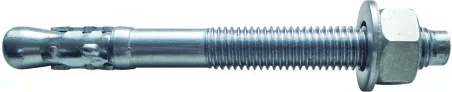

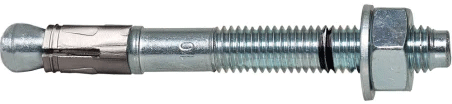

The zinc plated quick-fix anchor EKA is made of high quality steel. It is suitable for a wide variety of installations and diameters range from M6 till M20.

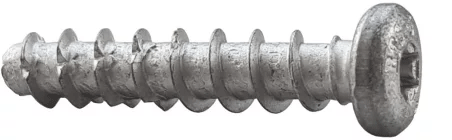

The concrete screw BTS5 PT with pan head (TX 25. head -Ø: 10 mm) is perfectly suited for a direct and fast fastening in different base materials with special capabilities into concrete.

Determining the safety factors is company-specific

The determination of the safety factor must be carefully considered.

In order to know the performance of a product, it is usually tested in in-house laboratories. If many tests are carried out here (more than 25) then there is a high probability of obtaining an accurate range of failure loads. Consequently, the safety factor need not be chosen so high, as the risk of failure can be estimated well (chosen factors for example 3 or 4).

If the number of tests is smaller or the scatter of the results larger, then the safety factor is chosen higher.

The condition of the substrate has an additional influence on the determination of the safety factor. Very even substrates (concrete, aerated concrete, solid bricks) show little fluctuation in the pull-out values. Therefore, smaller safety factors can be selected for these substrates. For perforated bricks or porous substrates, the scatter is greater and consequently the safety factor is also chosen to be greater (up to 7).

Factor of safety examples

An anchor is tested for pull-out in the laboratory. All tests show an average failure load of over 4 kN. We now set a safety factor for this anchor, in the example factor 4.

The recommended load capacity of this anchor on pull-out is thus given as 1 kN.

A safety factor of 4 means, for example, that the anchor can withstand a load 4 times higher than the recommended load capacity allows.

Responsibility for the recommended loads

Ultimately, in addition to the quality of the product, we (CELO) are also responsible for the recommended load and that is why we always err on the safe side when choosing the safety factor.

Factor of safety for approved products

Anchors that undergo an approval procedure are tested extremely elaborately and in many installation situations (heat, wetness, cracks in the substrate, different drill diameters, permanent loads, etc.) by external accredited test institutes.

Because of the large number of tests, one has a very precise overview of the behaviour and load-bearing capacity of the anchor. Some of our approved products are shown in the following images.

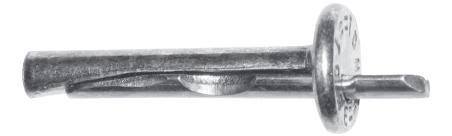

The suspended ceiling anchor MDA is ETA-approved for your safety as a fixing system for multiple use in non-structural applications in cracked and non-cracked concrete.

The high performance quick-fix anchor BAZ plus is suitable for a wide range of fixings in cracked and non-cracked concrete.

Safety factors for fastening products with approval are officially determined

In the case of European-approved products (these are actually referred to as European-rated products), the so-called partial safety factors apply as safety factors, e.g. these are 1.5 times for concrete, 2.5 times for masonry, 1.4 times for external loads, etc. These are then often also cumulated. These are then often applied cumulatively.

Similar values apply to nationally approved products. In some cases, further applications are tested here.

In addition to the specified safety factors, the failure frequencies are evaluated with a very low fractile (5%).

Determination of the load-bearing capacity

The load-bearing capacities are officially determined by the external test institute and the building authorities after the tests have been completed. The manufacturer of the product has little influence here. Therefore, in the case of approved anchors and anchors, it is all the more important that the manufacturer always produces a consistently good quality fastener.

Why the factor of safety is so important

The safety factor is an important aspect in the design and determination of the load-bearing capacities of fastening products. Safety factors help to account for uncertainties and variations in loads, forces, material properties and other factors. Safety and performance of systems and structures should remain guaranteed, no one should come to harm, for which a suitably selected safety factor is the prerequisite.